Grow your

social channels

to the next level

Kickstart your Instagram, Youtube, Spotify &

other channels presence, credibility & interactions

with the incredible service of the Top Rated

Social Media Marketing Company

Grow your

social channels

to the next level

Kickstart your Instagram, Youtube, Spotify

& other channels presence, credibility &

interactions with the incredible service

of the Top Rated Social Media

Marketing Company

Top 3 reasons to choose BuildMyPlays

| High Quality & Fast Delivery Customers surely receive 100% high-quality services and delivered within 24 hours. |

| Retention Guarantee Money-back and Retention guarantee are applied on all packages. |

| Customer Support 24/7 It doesn’t matter if it’s 3AM or middle of the day, we are always here to help. |

Top 3 reasons to choose BuildMyPlays

| High Quality & Fast Delivery Customers surely receive 100% high-quality services and delivered within 24 hours. |

| Retention Guarantee Money-back and Retention guarantee are applied on all packages. |

| Customer Support 24/7 It doesn’t matter if it’s 3AM or middle of the day, we are always here to help. |

Our Services

| Gain high quality & targeted followers, likes & comments. Be viral can’t be easier. |

Instagram Followers >>

Starting from $0.036/Follower

Automatic Instagram Likes/Views >>

Starting from $0.022/Like, $0.004/View

Instagram Likes, Views & Comments >>

Starting from $0.075/Like, $0.009/View, $1/Comment

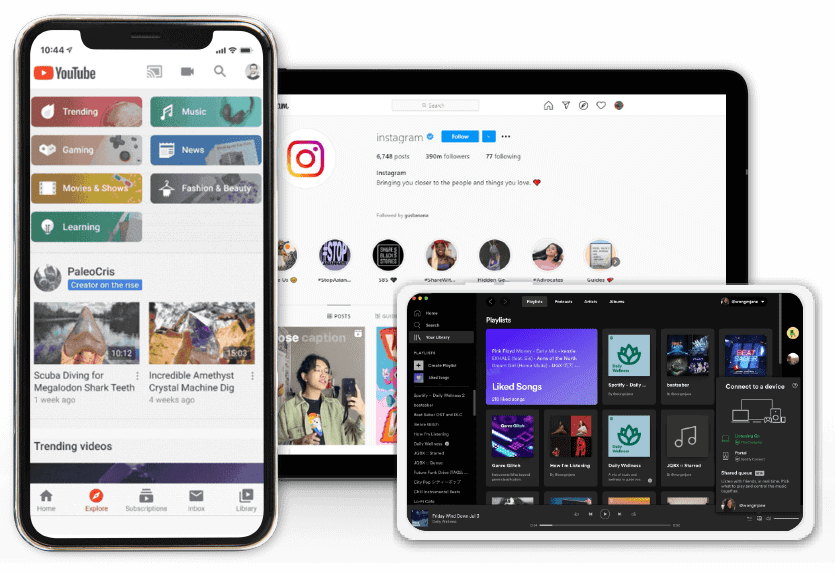

| Get safe, HR YouTube views on all of your videos instantly. Success is just a few clicks away. |

HR YouTube Views >>

Starting from $0.017/View

YouTube Subscribers >>

Starting from $0.18/Subcriber

YouTube Likes and Comments >>

Starting from $0.12/Like, $0.5/Dislike, $2/Comment

| Gain more followers and views easily with 100% satisfaction guaranteed services. |

TikTok Followers >>

Starting from $0.036/Follower

TikTok Views >>

Starting from $0.0018/View

TikTok Likes >>

Starting from $0.03/Like

| The quickest way to gain more followers and plays. Enhance your music career on Spotify. |

Spotify Plays >>

Starting from $0.012/Play

Spotify Followers >>

Starting from $0.03/Follower

Spotify Monthly Listeners >>

Starting from $0.01/Listener

| Attract more listeners, followers & engagements easily. Just focus on making awesome music. |

SoundCloud Plays >>

Starting from $0.0024/Play

SoundCloud Followers >>

Starting from $0.12/Follower

SoundCloud Likes, Reposts & Comments >>

Starting from $0.09/Like, $0.12/Repost, $0.8/Comment

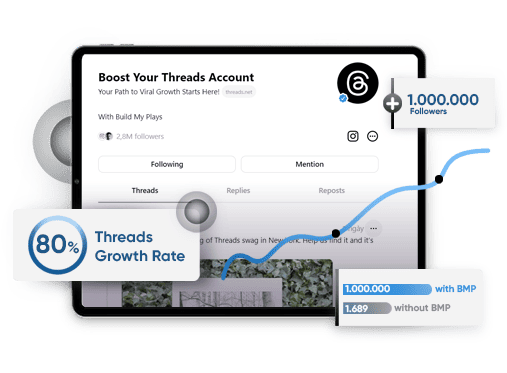

| Gain more Threads followers and likes can not be easier. Get ahead of the game! |

Instagram Threads Followers>>

Starting from $0.04/Follower

Instagram Threads Automatic Likes>>

Starting from $0.04/Like

Instagram Threads Likes>>

Starting from $0.045/Like

| Easy way to boost your page likes, post likes, comments and everything else… |

Facebook Page Likes >>

Starting from $0.072/Like

Facebook Profile Followers >>

Starting from $0.036/Follower

Facebook Post Likes, Shares & Comments >>

Starting from $0.08/Like, $1/Comment

| Gain more followers, receive automatic retweets & favorites, get recommended by popular influencers. |

Twitter Followers >>

Starting from $0.06/Follower

Twitter Retweets and Favorites >>

Starting from $0.18/Like, $0.18/Retweet

Automatic Twitter Likes/Retweets >>

Starting from $0.04/Like, $0.06/Retweet

| Buy awesome Mixcloud followers, plays, likes & repost. 100% satisfaction guaranteed. |

MixCloud Plays >>

Starting from $0.0012/Play

MixCloud Followers >>

Starting from $0.1/Follower

MixCloud Likes & Reposts >>

Starting from $0.09/Like, $0.09/Repost

Our Services

| Gain high quality & targeted followers, likes & comments. Be viral can’t be easier. |

Instagram Followers >>

Starting from $0.036/Follower

Automatic Instagram Likes/Views >>

Starting from $0.022/Like, $0.004/View

Instagram Likes, Views & Comments>>

Starting from $0.075/Like, $0.009/View, $1/Comment

| Get safe, HR YouTube views on all of your videos instantly. Success is just a few clicks away. |

HR YouTube Views >>

Starting from $0.017/View

YouTube Subscribers >>

Starting from $0.18/Subcriber

YouTube Likes and Comments >>

Starting from $0.12/Like, $0.5/Dislike, $2/Comment

| Gain more followers and views easily with 100% satisfaction guaranteed services. |

TikTok Followers >>

Starting from $0.036/Follower

TikTok Views >>

Starting from $0.0018/View

TikTok Likes >>

Starting from $0.03/Like

| The quickest way to gain more followers and plays. Enhance your music career on Spotify. |

Spotify Plays >>

Starting from $0.012/Play

Spotify Followers >>

Starting from $0.03/Follower

Spotify Monthly Listeners >>

Starting from $0.01/Listener

| Attract more listeners, followers & engagements easily. Just focus on making awesome music. |

SoundCloud Plays >>

Starting from $0.0024/Play

SoundCloud Followers >>

Starting from $0.12/Follower

SoundCloud Likes, Reposts & Comments >>

Starting from $0.09/Like, $0.12/Repost, $0.8/Comment

| Gain more Threads followers and likes can not be easier. Get ahead of the game! |

Instagram Threads Followers>>

Starting from $0.04/Follower

Instagram Threads Automatic Likes>>

Starting from $0.04/Like

Instagram Threads Likes>>

Starting from $0.045/Like

| Easy way to boost your page likes, post likes, comments and everything else… |

Facebook Page Likes >>

Starting from $0.072/Like

Facebook Profile Followers >>

Starting from $0.036/Follower

Facebook Post Likes, Shares & Comments >>

Starting from $0.08/Like, $1/Comment

| Gain more followers, receive automatic retweets & favorites, get recommended by popular influencers. |

Twitter Followers >>

Starting from $0.06/Follower

Twitter Retweets and Favorites >>

Starting from $0.18/Like, $0.18/Retweet

Automatic Twitter Likes/Retweets >>

Starting from $0.04/Like, $0.06/Retweet

| Buy awesome Mixcloud followers, plays, likes & repost. 100% satisfaction guaranteed. |

MixCloud Plays >>

Starting from $0.0012/Play

MixCloud Followers >>

Starting from $0.1/Follower

MixCloud Likes & Reposts >>

Starting from $0.09/Like, $0.09/Repost

Customers

100,000+

Projects Promoted

140,000+

Followers delivered

14,377,688

Views/Plays delivered

75,614,430

Customers

100,000+

Projects Promoted

140,000+

Followers delivered

14,377,688

Views delivered

75,614,430

Customer Feedback & Reviews

Here at BMP we pride ourselves in exceptional service and affordable prices.

Don’t just take our word for it – check out what customers say about our products below.

Customer Feedback & Reviews

Here at BMP we pride ourselves in exceptional service and affordable prices.

Don’t just take our word for it – check out what customers say about our products below.

How it works

Step 1

Place Order

Step 2

Receive Confirmation Email

Step 3

Start promoting with partner

Step 4

Enjoy the result with 90 Days Guarantee

How it works

Step 1

Place order

Step 2

Receive Confirmation Email

.

Step 3

Start promoting with partners

Step 4

Enjoy the result

Your Social Media Success Starts Right Here

Would you like to read?

We share a range of different topics quite often. Make sure to check out our blog if you want to stay in touch with the latest news … and beyond!